Vorsprung durch Technik – Durango DEX410

Team Durango’s DEX410 is possibly the most anticipated electric 4WD buggy of all times! We think this is not a exaggeration as the handmade prototypes (designed and build by German racer Gerd Strenge) are around for many years now but only made it into the hands of some selected team drivers like Jörn Neumann, Billy Easton, Atsushi Hara, Craig Drescher or Mark Pavidis to name just a few. Now ‘The Durango’ is available for everyone thanks to Gerd Strenge and his designer Michael Vollmer who made the impossible possible and took the challenge to create ‘a Durango’ for the mass market. We got our hands on one of the very first kits of this exciting new buggy.

Introduction

The reason why the Durango prototypes have been so legendary is the fact that they are so different from everything that has seen the light of the day before. The chassis was super slim, the body looked more of a fish than a buggy and last but not least the cars always proved to be super-fast! This was proven by Jörn Neumann (European Champion 2004 with the Durango) on more than one occasions. Being an ultra-rare buggy also added to the ‘must have’ factor. From the beginning Gerd was asked more than once to make cars for solvent buyers … Now, this is something that has changed as now you can have a Team Durango ride for only a couple of hundred (not thousand!) US Dollars, British Pounds or Euros. Now you may wonder where that strange sounding name comes from. We did too so here’s the conclusion: Durango Electric Xross (like ‘off-road’) 4WD 1/10 scale.

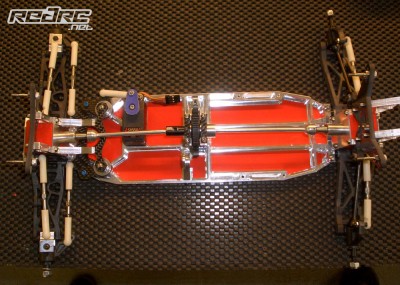

Front

The front of the DEX410 sports a quite unique set-up for an 1/10 scale electric buggy. While most of the other belt and shaft driven 4WD buggies come with split two piece differential cases the Durango has two vertical bulkheads screwed down to the chassis plate. Now a smaller vertically split differential case is inserted from the front secured by only four screws. This system is seen on some 1/8 scale buggies and truggies and makes maintaining and tuning the gear differentials a breeze. The set-up may look more complicated compared to the ‘usual’ design but has loads of advantages – the quick access is only one of them.

Inside the differential case another renunciation from the average 1/10 electric competition buggy design can be seen: the geared differentials. Yes, ladies and gentlemen, geared differentials on a full breed racing buggy. Normally seen on entry level buggies the geared differentials not only withstand the rigours of LiPo batteries and high-reving brushless motors better than ball diffs but also offer maximum, non-slipping traction.

The suspension duties are taken car of a pair of very sturdy plastic composite wishbones. They are held in place by alloy suspension holders with pivot-balls in which the suspension pins are located. At the moment only one geometry is offered but given the design of the parts we reckon optional suspension brackets with different kick-up and/or toe rates will follow. The alloy caster blocks with laser-etched Team Durango logo are not only a piece of art but also offer a lot of set-up potential. The height of the steering spindles is changeable via 1 and 2 mm thick orange alloy shims. Also the length and height of the upper turnbuckle is adjustable via shims and two different locating holes.

Drive to the wheels is taken care of by a nicely made set of steel universals. On the differential side the drive pins are protected by rubber boots that sit on plastic rings that are pressed onto the differential outdrives. These plastic rings not only locate the rubber parts but also keep away smaller stones and most of the dirt from the diff bearings. The wheels axles sport the common ‘Losi’ hex which means you can use your familiar rims like Losi, JConcepts, Associated or the new and very stylish Team Durango rims that not only look good but also protect the wheel nut thanks to a raised cone around the nut. Part of the standard set-up is a set of 1.3 and 1.5 mm roll-bars. Although the manual stated to use the thicker 1.5 mm part we used the 1.3 mm wire as the initial test took place on a dusty low bite track.

One of the most important parts of the front end are definitely the simply stunning oil-filled shock absorbers. They sport a threaded alloy body and end cap, a thick shock shaft and, most importantly, rubber shock boots with bump stops. Alternatively, for low-dust conditions for example, you can build them without rubber boots and only add the supplied rubber shims as bumps stops. The kit also included alloy shims to further limit the up travel. The DEX410 comes without shock oil and therefore we pretty much copied Gerd Strenges German Nationals set-up (PDF) with 22.5wt oil front and rear. The shocks attach to a very thick 4mm carbon shock tower that offers three different mounting holes for the upper part of the shock and a total of six different holes to mount the upper links in.

The steering has always been an integral part of the former Durango prototypes. Very compact, very low in its appearance and, most importantly, actuated by Futaba’s low-profile S9550 servo. To overcome the problem of being bounded to only one specific servo Gerd and Michael of Team Durango developed a very compact steering that incorporates every standard sized servo and also consists of a minimum of parts. The main part is a machines alloy frame in which the servo is screwed in. Left and right of the servo sit the inner steering levers with an integrated adjustable servo saver. The steering link is a bow-type alloy plate that pivot on ball bearings and offers three different steering Ackermann positions to adjust the steering feeling. The whole steering set-up is screwed to the chassis plate with only four screws making it super fast to extract for cleaning or maintenance reasons.