BMI Racing DB12RR 1/12th scale chassis

Over the past year and a half, BMI Racing have spent alot of time monitoring the performance of their car. As they are always looking to improve and strive to stay ahead of the competition, they have revamped an already good design and made it even better, the result, the DB12RR. The goal of this new version of the DB12R is the same as the goal that spawned the original car….Faster lap times, maximum versatility and ease of driving at the limit. The changes made to the DB12RR fall into three categories, performance improvements, brushless motor optimization and serviceability improvements.

Click here to read more…

Performance Improvements

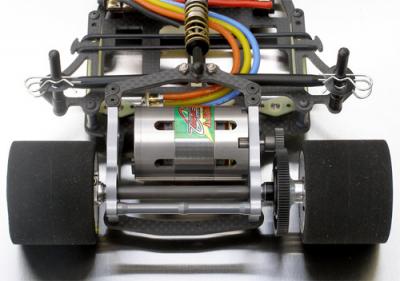

The focus of performance improvements on the DB12RR is centered on the rear suspension and pod. The lower rear pod has been made longer with no increase in overall wheelbase. Everything has been moved on the main chassis in order to maintain ideal weight distribution and chassis dynamics. This change alters the leverage ratio of the pod as it acts on the center shock and main chassis. The effect of this change is more corner speed and a more free rear end. The DB12R always had an abundance of rear traction. This is one reason why it was so great on asphalt. The DB12RR allows for this same level of traction but makes it very easy to shed it when necessary. The car changes directions extremely fast and can be made

to be very aggressive while limiting excess chassis roll. As a result you will get more mid corner and exit steering and higher corner speeds without a loss in corner entry steering.

The DB12RR also features an X/Y axis centered shock mount on the rear pod. This puts the upper shock pivot in line with the central pivot. This change alters the leverage of the pod over the center shock which makes the car handle bumps much more efficiently and improves rotation. We also offer 4 different forward shock mounting options for shock length adjustment to further tune the desired amount of rear traction. The DB12RR features new longer flex plates. The new flex plates have two mounting positions. A new longer, linear position for conditions where you do not want the more progressive side to side spring rate, such as when you’re on high grip carpet, and the standard short position for asphalt and low grip surfaces where you need aggressive weight transfer to get the steering you need.

The DB12RR now comes standard with the one piece cross brace that was optional on the DB12R. Also new for this kit are flanged chassis stand offs, just because they look cool. The DB12RR now comes standard with lowered rear pod plates that lower the rear axle 2mm over the standard pod. This enables racers to run their rear tires almost down to the rim if necessary.

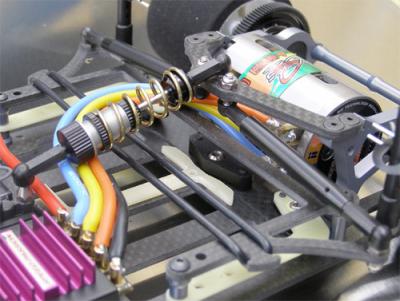

Brushless Motor Optimization

The DB12RR is truly optimized for Brushless motors. There are no short cuts or compromises here. The new offset right rear hub that was designed in collaboration with IRS was critical to optimizing the rear pod for a brushless motor. This new hub allowed us to move the motor pod plate thus centering the longer brushless motors and allowing a simple drop in fit for ANY brushless motor on the market. You can even change motors with the pinion still attached!

The DB12RR is the first production 1/12th scale car to feature the new offset IRS hub. Another benefit of the longer rear pod is a massive increase in the gearing capabilities of the DB12RR. You can fit up to 143 teeth between the pinion and spur with 64P gears. That means you can run up to a 100 spur with a 43 pinion….or a 78 spur with up to a 65 pinion if you can find one that big! This makes it easy to gear 17.5 and 21.5 motors on 4 cells and, looking forward, enables racers to get the gear ratios needed to run 3.7v LiPo.

Serviceability Improvements

In addition to the previously mentioned improvements regarding drop in motor fitting the DB12RR features slots in the main chassis for the servo mounting. This enables racers to fit any brand servo and center the output shaft perfectly without flipping the servo to the opposite side of the chassis. There are two threaded holes in the bottom of the servo mounts so racers can fit the servo offset forward or back for weight distribution changes. The servo mounts also allow racers to run the servo flat or angled in order to achieve the desired ackermann for the racing surface and track layout. The DB12RR uses an o-ring to retain the batteries. This functions perfectly but some racers prefer to use tape. The DB12RR has been refined to make it easier to use tape. The chassis slots are now beveled and increased clearance has been made in the cross brace to make it easy to tape your cells in.

Source: BMI Racing [bmiracing.com]