Xray T3 – History Repeating

Middle

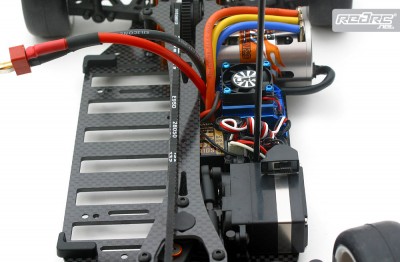

The new 2.5 mm thick carbon fibre chassis plate is of a asymmetrical design and around 6 mm wider on the right side where the battery locates. This is to make way for the front belt if you wish to run the special ‘LiPo’ drivetrain set-up.

With the T3 you have the choice to run the front belt on the right side of the chassis which in turn gives you the possibility to mount the somewhat heavy items like the speed controller and receiver near the car’s centre of gravity. This is quite a unique feature on the T3 and obviously one of the most important ones as the weight distribution has a huge influence in the overall performance of a competition car. The ‘LiPo conversion’ is simply done by flipping the drivetrain around. Unfortunately Xray’s own ‘Multi-Diff’ can not be used with the alternative LiPo set-up as you also flip the axles around which, with a front one-way, would result in a full-time 4WD drivetrain under braking and a 2WD drivetrain under acceleration! With the standard differential in the US Spec and spool axle in the EU Spec version this is no problem of course.

Rear

The rear of the T3 shows a revised bulkhead just like the one up front. The motor holder is now shorter and makes the motor sit 3mm closer to the centre line of the chassis The rear bulkhead that houses the ball differential is longer as well as higher compared to the one used on the T2 ‘009 as it needs to make way for the chassis-mounted suspension holders. The mainshaft, as well as the supporting bearings, are now sandwiched between the bulkhead and the top deck rather having them stick out of the top plate. The top plate is also now longer and of a one-piece design compared to the ‘009 item. The bearing holders of the layshaft attach to the bulkhead via screws making it possible to detach the upper mounting screw to gain more chassis flex and thus more rear traction.

The rear end of the T3 feature the same ‘Quick Roll-Centers’ for the upper camber links but sports a revised shock tower with updated inner camber link positions. Xray did away with the additional lower hole for the QRC reducing the amount of mounting positions from six to four which is still enough to play with.

The rear springs supplied with the kit are still C2.6 ones while the swaybar now comes in 1.2 mm guise instead of the thicker 1.4 mm item on the ‘009. This again is to adjust the basic set-up to the lighter LiPo batteries and a total weight of the T3 of around 1250 grams.

New to the T3 are the 38 teeth differential pullies giving and internal ratio of 1.9:1 instead of 1.7:1 with the T2 ‘009. Also the differential outdrives are now black hard anodised rather that the traditional grey/green colour with the ‘009 item. We heard of some drivers who complained about differential rings that slip on the black outdrives due to the slicker surface but our guess is that this might not be a bad behavior as this gives a certain protection to the diff rings and diff balls as the rings slip on the outdrives before the rings and balls do. Maybe it is even meant this way but Xray forgot to mention it?

Finish

Electronic-wise we used a nice potpourri of parts we had at hand. We opted for LPR’s SXX TC Spec speedo, Team Orion’s Carbon Molecular LiPo batteries and an Speed Passion Competition 2.0 5.5T motor. The Blitz Altis body was painted by Kai Kobüssen of www.ok-gfx.de