Making the Xray RX8’16 – Part 1

I have a lot of respect and passion for the 1/8 on-road class. My passion comes from my early days when I got involved in RC, as this was the class I started with and grew up with. My respect comes from the fact that this class is considered the “ultimate F1 class” and as such many manufacturers put a high priority and investment into the class that pushes performance and limits all the time. It is kind of strange that despite this class being considered to be pinnacle of all RC car classes, the number of race entries is still low. This is understandable considering the big investment for a 1/8 on-road season and the complexity of the cars, but the very high speeds make the races very exciting and also challenging!

For non-involved persons it may seem that the cars remain nearly the same, but the opposite is true. Since many manufacturers make this class their primary focus, there are large resources invested into R&D and as such new changes & refinements appear every year. Every brand and every team that takes this class seriously must stay constantly involved, participate at races, and have frequent interaction with the community. Quite literally, there is no time for a break.

My father Juraj Hudy was designing & producing his own 1/8 on-road cars by himself in the late 70’s, but Xray’s first commercially-available, mass produced 1/8 on-road platform was the RX8 which was introduced back in 2010. Since its introduction, we have made huge progress on the car and worked hard with the team during the seasons to bring improvements for the next car… cars which were again faster, better, and more reliable than the last. This is pretty much what we do with all Xray cars and platforms, in all classes.

Even with our best efforts, 2015 was the first year that we did not release a new version of the RX8. It was an extremely difficult decision to make, but we had to face reality though it was not to my liking. Why? New tire rules brought numerous new challenges which we had to solve; though I started with some small changes and ideas, we ended up designing an all-new car. How? Keep reading!

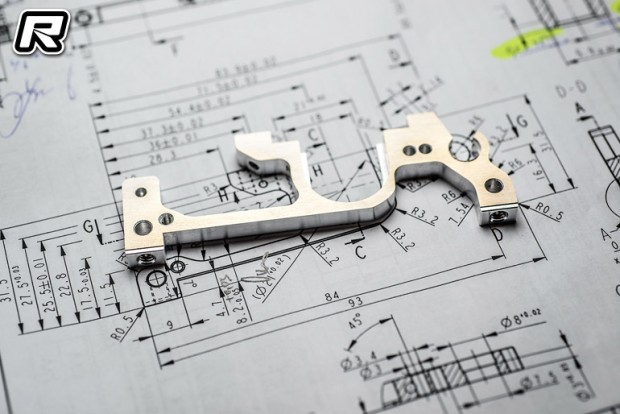

Back in 2014 we were probably the last manufacturer that continued to use composite bulkheads. These were great for soft tires, but now that hard tires had to be used we were forced to completely redesign the entire platform. I thought I could make all the changes fairly quickly, but I ended up in an endless loop of design-prototype-test and back to design again. During the over 1.5 years of development (and seemingly never-ending testing), I ended up with 12 different concepts. Yes, that’s right… 12. Twelve different designs, from which 4 different designs were realized into real prototypes that were tested and analyzed. Does this sound crazy to you? Yes, it is crazy for sure, but once I got fully involved and had a clear goal of no-compromise strategy, there was no turning back.

Most of the work and development was in the following critical areas:

– FLEX: Flex is the most important feature that influences the overall characteristics and handling of the car. All changes to the car were made with the intention to achieve the proper flex, and of course to design the key parts to allow flex adjustment as needed.

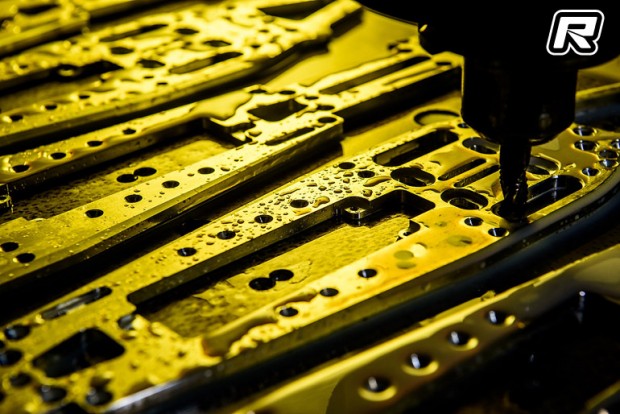

– BULKHEADS: The aluminum backbone of the car was a major update to the entire concept of the car, a “must have” when using hard, large tires without additive. With experience from the recent NT1 platform redesign changing to aluminum bulkheads, I already knew the critical things to focus on, and how to incorporate new parts to allow the car to flex properly. I also knew how to re-design the car to make it easier to work on, as well as keeping production efficiency in mind.

– CHASSIS: The chassis was re-designed to work with the new aluminum backbone, and it was modified to accommodate the newly-improved geometry.

– SUSPENSION FLEX: Flex of the suspension is very important to the car’s overall performance and handling characteristics. Besides getting the correct stiffness of the composite suspension arms, the way that the suspension is mounted is also very important. Therefore I focused on this area and tested many different alternatives that helped me to make good progress.

The car’s flex and suspension are things that you cannot analyze in a computer environment, but rather they have to be experienced on the track. As such, whatever I designed in the computer was soon tested on the track. To be sure that I had feedback from all different track conditions, we decided to make more prototypes than usual. We tested the prototypes at low-traction tracks in Portugal and Slovenia, at large open tracks in Germany, and at tight tracks (with boards) in the USA. With different tire additive rules from country to country, we needed to test at races which allowed tire additives (e.g., Italy, USA) as well as at EFRA races which did not allow tire additives.

The test team included Bruno Coelho (Portugal), Nicola Marrone (Italy), Fabio Domanin (Italy), Mattia Passenti (Switzerland), Tom Kraegefski (Germany), Mike Swauger (USA), Ralph Burch (USA), Jernej Vuga (Slovenia), and of course myself and my father Juraj. To get feedback from regular drivers as well, I included Tomas & Igor Lipták – they are living in my city, and are both RC fanatics that spend almost every day at our track. Both of them together put in several hundreds of track time hours, so I could be confident in the car’s long-term reliability.

Prototype #1:

After the 2014 season, I started working from scratch using concepts from the new NT1. I started with the design of the alu bulkheads, which were assembled to the RX8 chassis. I tried to use as many existing RX8 parts as possible, but of course there were many complications and thousands of small problems. In the computer, I created several different concepts which had the same results, but every one of them used different parts to achieve that. From these first concepts I chose the one that used the most existing RX8 parts so we could quickly create prototypes for the team to test. It took several weeks to produce the new parts, but after I assembled the first car and checked the flex on the workbench I was very positive and optimistic.

The first feedback was positive (as expected) and everyone reported that the first prototype performed better than the current RX8 car, and in particular it had increased traction and steering. I was happy that we started to move forward right away from the beginning, but I wanted to wait for a few more weeks to get more feedback from the rest of the team. From all the data we collected along with my own test experiences, I knew what I needed to work on next.

Prototype #2:

Based on Prototype #1, I started to work on further modifications and improvements. The basis of Prototype #1 was very good, so I only needed to work on small details to make the car easy to handle but also easier to work on. There were several parts that required design changes to eliminate weaknesses. For example, I received reports from two different drivers who both broke aluminum bulkheads in exactly same place. As such, I had to completely redesign the front bulkheads to make them stronger and more reliable, while still keeping the same flex. Progress with Prototype #2 was going very well, but time was flying by faster than I realized.

While I was hard at work, I was suddenly confronted by the most difficult thing that any designer and engineer faces: The Deadline. By then it was the beginning of 2015, and we had only a few months left before the new season started. I had a major decision to make: either we were all done and ready for mass production, or we continue to work on the design which would put us in jeopardy of missing the start of the season… which also meant the potential of a drastic drop in sales.

I spent many sleepless nights thinking about all the details and aspects of the project, but to move forward there was no other option than to analyze all the feedback and consider all the options in front of me (again). There were so many different ideas for improvement which I was convinced would give even better performance, and I really did not want to miss out on them. I badly wanted to bring the RX8 to the top of the class, which was probably the reason I lost track of time. I kept trying to convince myself that we could still do everything on time.

After very tough considerations, I decided to take a risk and continue to incorporate new ideas. I really did not want to make any compromises, and wanted to make the RX8 the absolute best possible. I was convinced that I could quickly incorporate all the necessary design changes, produce the prototypes quickly, have them tested quickly, and then still be on time to incorporate any changes before mass production (which, of course, could still be on time). Oh man, how wrong I was!

The first delay happened right away in the design process, as I had some very different requirements and ideas from the team which I could not incorporate into a single design. As such, I ended up with another 3 different designs and platforms. So what I thought would only take me a few hours behind the computer actually took me many, many days… more than I expected. Then to produce all those different prototypes for 3 different designs also took much more time… so again, we spent much more time in production than expected. Once the prototypes were finished, I sent them to the drivers for testing and anxiously waited for feedback while Juraj and I continued to test.

Time was flying by very fast, and I was getting very close to The Deadline. To say I was seriously nervous and stressed is a gross understatement. I had a really good feeling about the progress we made from my own testing as well as from others’ feedback, but the more feedback I got the more I realized I was in real trouble. After all the information was analyzed, I simply did not know which way to go since each of the 3 different concepts had different strengths but also some weaknesses. Of course, some of the weaknesses could be quickly changed & incorporated, but the tricky part was that it started to seem that the only solution would be to “mix” and incorporate all the 3 different concepts into 1 design. This would be the ideal solution, but would mean a very high chance of missing The Deadline and the beginning of the season. The pressure was tremendous.

I had to decide whether to:

a) select one of the 3 concepts and put one of them into production, or

b) get back to work and make new changes.

If I selected the first option, it would not be a disaster as any of the 3 different cars were still a big improvement over the previous RX8. But still, all of them had room for improvement which I knew about and could not get out of my head.

Should I play it safe and compromise… releasing a car on time for the season? Or should I stand by our “no compromise” commitment to ensure that I put the best-of-the-best into the final design?

After extensive analysis of how quickly we could run the production line, I decided on the riskier of my two options. It was obvious that if I still wanted to make changes, there was no chance to produce a prototype, test it, and then run mass production… all while still being on time. I decided to make all the required changes I had in mind, and produce a small quantity of cars in the final design for the team. With this strategy I wanted to at least have the team running with the new car, meanwhile running the mass production as quickly as possible. This would essentially mean that despite missing the start of the season, we still could have the car available a short time afterwards. Whether or not this was the right decision I will never know, but the fact is that in the end we missed the season.

Check back on Monday for the Part 2 of this behind the scenes story of the 2016 RX8.