Awesomatix A12 1/12th scale chassis

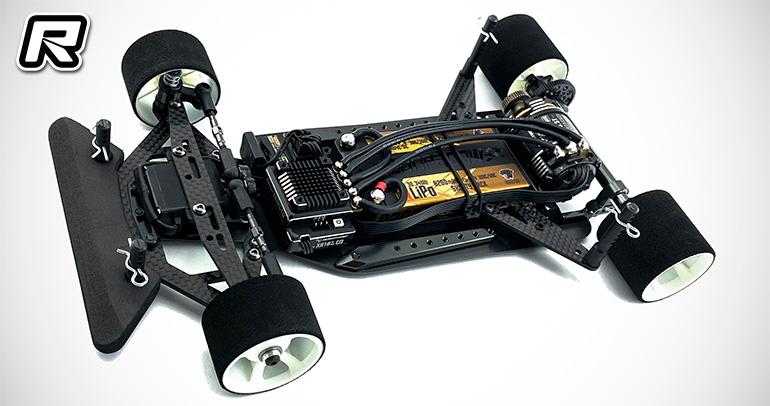

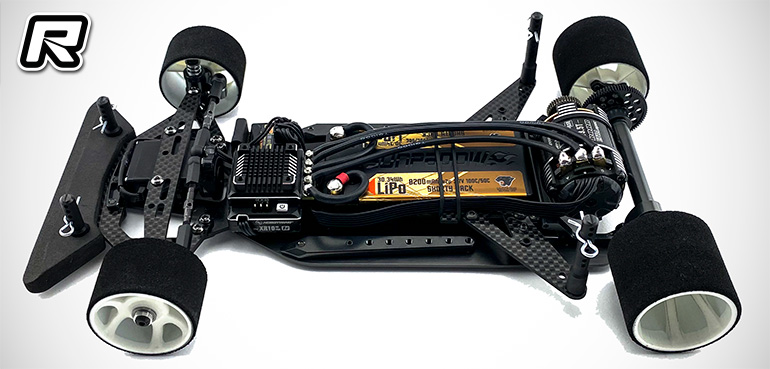

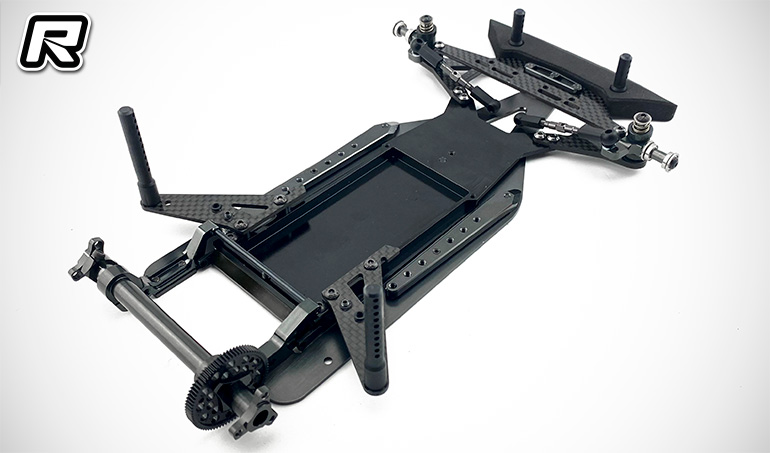

Having previously shown you prototype photos of Awesomatix’ radical new A12 1/12th scale chassis, today the Russian company have released final details & photos of their soon to be available car. The first thing you notice about the A12 is simply how low it sits. A low centre of gravity is a critical element in racing performance for any class, and this is further exemplified by the A12 pan car on an entirely new level. Much like the Awesomatix A800MMX touring car, the A12 far surpasses all existing 12th scales by providing a much lower centre of gravity.

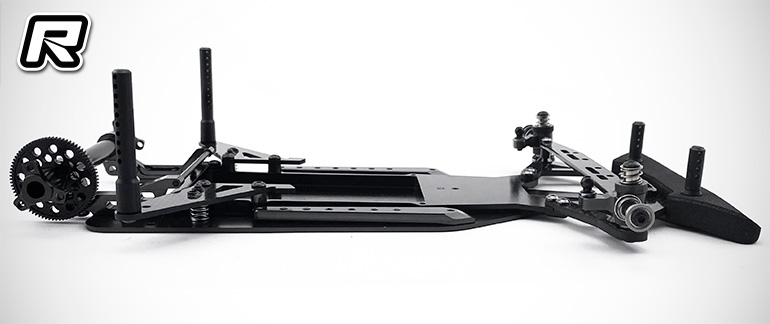

The Awesomatix A12 features a completely new design compared to any previous 12th scale car on the market. It does not have a standard lower deck / chassis and lower pod plate, but rather is composed of two parts that work in tandem and are connected with ball joints. The outer frame of these two suspension components contributes to the spring action of the car as it functions like a large spring. The inner frame contains the front end, servo, receiver, esc and battery. A hydraulic damper is built between these two parts of the frame, providing easily adjustable dampening and rear axle movement. The end result is a suspension and pivot movement that is similar to conventional 12th scale cars but has proven to be far more durable and tweak free.

Additionally, the alloy side braces on the outer spring frame offer several possibilities to play with rate of the “rear suspension” by simply moving and adjusting a set screw. The stiffness of the chassis can be adjusted very quickly for a variety of track conditions.

The A12 follows the Awesomatix tradition of innovation by using specially designed hydraulic rotary dampeners instead of traditional oil piston shocks. The A12 rear rotary damper unit is very compact in size and mounted at the lowest possible point on the chassis. Inside of the damper case are two rotary damper ‘vanes’ that work independently to ensure smooth and efficient dampening, which can be adjusted by different viscosity silicone oil. This carefully designed damper provides the required ratio between both the longitudinal and side dampening needed to excel on any track condition. This rear damper is easily removable, too, as just two screws allow for the “quick release” of the entire unit.

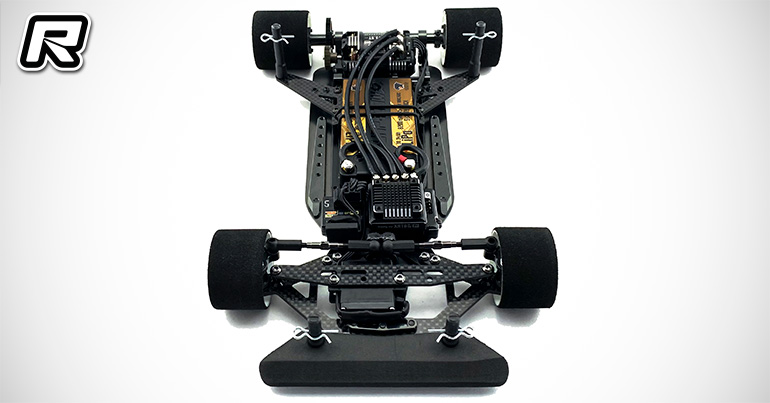

The 7075 T6 aluminium front hubs on the A12 have created a highly adjustable front end design. This kingpin design enables the use of different viscosity oil, grease, and o-rings within the front hubs along with traditional coil-over springs to ensure optimal performance on any racing surface. Setting the front end camber is quite simple and is done by turning the kingpin post. Predetermined holes in the front carbon suspension plate line up with predrilled holes in the kingpin post which together determine camber angle. This allows camber to be changed in 0.25 degree increments, from 0.75 to 1.75 degrees.

The A12’s stiff front bumper design matches the shape of the front carbon suspension plate and is cut at an angle to match the front-end shape of most commonly used body shells. Unlike most 12th scale kit bumpers, no hand fitment is required and the bumper’s stiffness helps prevent damage in the case of a crash.

The design concept of the car supports an inline battery and centralised electronics placement. The servo is mounted to the front end cross plate. Multiple sizes and shapes of servos can be used, up until a maximum dimension of 35mm x 30mm x 15mm. The ESC, receiver, servo and transponder are located in front of the battery. The rear rotary dampener is positioned under the battery at the back of the inner frame. The inner frame connects to the outer frame with 2 ball joints at the front end that allow it to pivot, and small hooks on each side of the damper vane connect it to the rear pod assembly to provide the ideal dampening level.

The carbon side wings offer two possibilities for both side spring placement and rear body posts position. The side spring positions offered on the car allow for variable side roll stiffness depending on the conditions. Depending on the body shell used and its mounting position, the narrow or wider holes may be more suitable to ensure no deformation of the body shell at high speeds.

Another Awesomatix innovation is an ultra-lightweight spring steel-alloy composite spool axle which uses a centre nut to quickly change the spur gear. The total weight of this fully-metal spool unit is less than the most competitors’ carbon spools but with far greater total strength and torsional rigidity.

The very light, solid circular aluminium rear beam provides exceptional rigidity and a tweak-free operation for the rear pod. This rear beam can be set in a short or long wheelbase position, and shims used under this beam set the desired ride height.

Special Features of the A12 Pan Car Kit:

– 7075-T6 2mm aluminium Outer Spring Frame

– 7075-T6 2mm aluminium Inner Frame

– Lowest centre of gravity design

– “No tweak pod” concept

– Rotary damper unit in rear

– Next Level Front End design

– 7075-T6 aluminium Front Hubs

– Quick and easy adjustability of setup change

– Rigid Frame design

– Carbon Front Suspension plate

– Ultra Lightweight Spool Axle

– Stiff and properly shaped Foam Bumper

Source: Awesomatix [facebook.com]