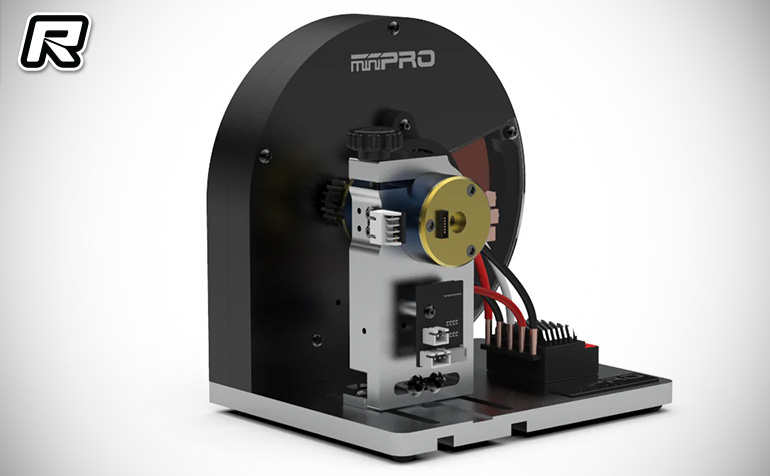

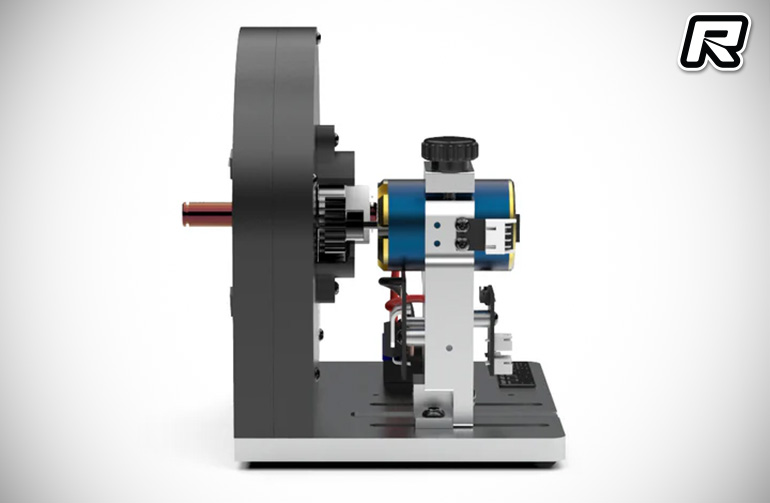

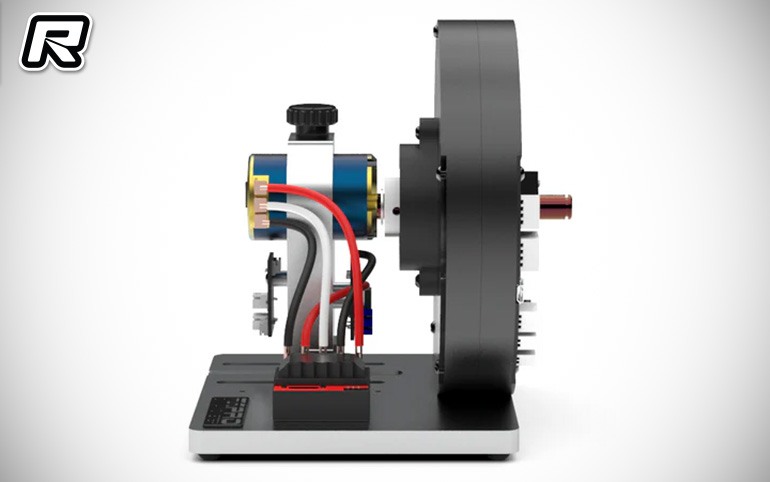

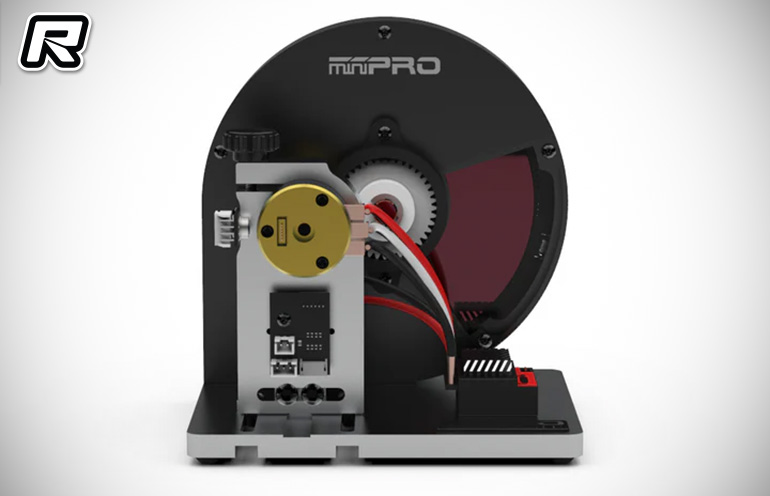

MiniPro Motor Dyno V2

Almost 8-years on from the launch of their first Motor Dyno, MiniPro has released a V2 version of the R/C Car Inertia Motor Dynamometer. The new V2 was designed for the testing all types of R/C motors, brushed or brushless. The load on the motor is produced by the inertia flywheel unit, a high quality 6061 aluminium frame cover around the flywheel to protect from high rpm speeds, and an embedded dyno board to accurately measure the acceleration of the DUT (device under test). The dyno uses a pinion/gear combination to accelerate the inertial mass (flywheel). Its embedded dyno board takes the flywheel’s inertia (resistance of an object to a change in its state of motion), and measures the rate it takes to accelerate it and calculates the output power and torque of the DUT. The dyno repeatedly measures and calculates power in small increments to produce an accurate graph on a PC of the motor’s power characteristics. Precise, otherwise known as “Repeatability” is what you want in a dyno, that means test the same electric motor time after time and get the same results. The V2 dyno is capable of repeatable test results using the built-in Throttle controller sensor (license required).

MEASUREMENTS

Motor RPM

No-Load RPM* (requires BLDC rpm sensor)

Kv (rpm/v)

Torque

Power-In (requires voltage & current sensor)

Power-Out

Up to three temperature readings (requires temperature sensor)

True Motor Temp* (requires BLDC rpm sensor)

Voltage (requires voltage & current sensor)

Current (requires voltage & current sensor)

mAh (requires voltage & current sensor)

Efficiency (requires voltage & current sensor)

FEATURES

Motor Power: up to 3,000W / 4hp (depends on flywheel)

Motor Speed: up to 100,000rpm (20,000 max @ flywheel)

Voltage: up to 50V (depends on selected sensor)

Current: up to 200A burst current (50A continued)

Low residual torque

Low dyno losses (no side load due to pinion/gear)

Repeatable motor installation

Ultra Low friction ceramic ball bearings

No load motor speed and temperature (BLDC rpm sensor)

Built-in Throttle Control Sensor (license required)

Built-in dyno controller board to measure RPM, Speed, RPM/V (Kv), Torque, Power and Efficiency.

Built-in Aluminium base and vibration resistant.

Load adjustability by using different flywheels, pinions and gears.

Compact and modular design

Compatible with Belt and Pulley system (older motor dyno versions)

Low maintenance

Source: MiniPro [minipro.com]